Hebei Shuangda Rubber & Plastic Machinery Co, Ltd. is a modern enterprise specializing in theresearch and development, production and sales of complete sets of rubber, silicone and plasticextrusion machinery. Our company has more than 20 years of production experience and currentlyhas 150 employees, including more than 30 R&D teams, 8 senior engineers, 5 quality inspectors, and20 after-sales personnel. Professionals provide you with personalized customized services. Thefactory equipment has passed ls0900 and CE testing certifcation, and the factory machines areexported to more than 20 countries overseas, including the United States, Russia, Spain, india andother countries.

Our company adheres to the principle of"customer-centric, honest and trustworthy" and regardsequipment quality as the life of the enterprise. Provide customers with high-quality equipment andservices, and provide comprehensive technical support.Purchasing our company's equipment can support factory installation and technical guidance, andthe products can be customized according to needs. Foreign customers are welcome to visit thefactory for guidance and business negotiations. We look forward to long-term cooperation with you.

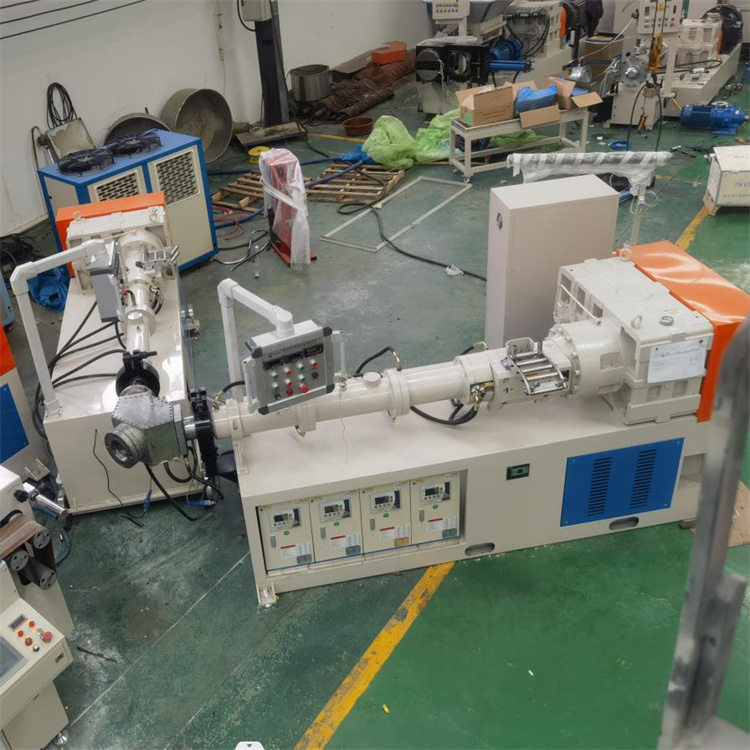

Rubber strip extruder with three compound head

Key words:

Rubber strip extruder with three compound head

Classification:

Rubber, rubber and plastic extrusion line

Email:

Whats App:

Rubber strip extruder with three compound head

1. Working principle

Extrusion molding is a process in which the plastic material is continuously pressed out through a mouth shape under specific conditions, so that it becomes a product with a cross-section shape.

When the rubber material moves forward along the screw, due to the result of mechanical action and thermal action, the viscosity and plasticity of the rubber material have changed and become a viscous fluid. According to the change of rubber in the extrusion process, the working part of the screw is generally divided into feeding section, compression section and extrusion section according to its different functions.

2. Cold feeding extrusion

Advantages: save heat refining equipment, easy to realize mechanization, automation, and because the main engine strengthens the shear and plasticization of the screw, so that the rubber material to obtain uniform temperature and plasticity; Improve the quality of extruded products, increase the surface finish, extruded semi-finished products have more stable and consistent size; The cold feeding pressure is less sensitive and flexible. The investment and production cost of cold - feed extruder is lower.

3. Equipment characteristics

Suitable for extruded rubber (EPDM, natural, butyl green, butyl, regeneration), used for building doors and Windows sealing strip, automotive sealing strip composite strip, single extrusion strip production and construction, electrical appliances, machinery, water conservancy and other different shapes of strip, strip, tube, plate and other dense and foamed rubber products.

Cold feeding rubber seal extruder: It is a kind of equipment that uses cold rubber to produce. The feeding way of the equipment is generally strong refrigeration feeding. The cold - fed rubber extruder is characterized by high production efficiency and stable production. Generally, extruder is used to produce seals, rubber tubes and other products that can be produced by extrusion process. Extruder is used for extruding tread, inner tube, rubber hose and rubber type strip rubber machinery.

ABOUT US

CERTIFICATES

With the multiple certificates in markets, our clients must have great confidence in our productsFirst and foremost, the quality assured,

OUR EXHIBITION

CUSTOMER FACTORY VISIT

PACKING & DELIVERY

SHIPPING

MSK/MSC/CMA/COSCO/HPL/HMM/YML ETC.

PAYMENT

FAQ

Q:Do you have equipment to see it live?

A:Yes. Welcome everyone's arrival

Q:Equipment delivery time?

A:The delivery time of equipment generally takes more than 30-60 days

Q:How to deal with orders?

A:Let us first know your request or application.Second, we quote your request or our suggestion.Third, the customer confirms the required equipment and deposits it into a formal orderFourth, we arrange production.

Q:Do you provide product warranty?

A:Yes, we provide a one-year warranty for our products.

Q:How to handle the error?

A:First of all, our products are produced under strict quality control system with a failurerate of less than 0.1%.Second, during the warranty period (except for wearing parts), we solve the problem byphone or by video. For big problems, we will arrange technician on-site debugging.

Q:After the purchase of equipment, to provide overseas installation andcommissioning services?

A:Yes, we will arrange technical personnel to the site to install and debug.

All specifications and designs are subject to change without notice.

According to the customer's request.

Related products

Feedback

Shuangda

Hebei Shuangda Rubber Machinery Co., Ltd.

Whats App:+8619931982593

Email:xu@hbshuangda.com

Official website:www.shuangdasuji.com

Addr:Liyuantun Industrial Zone, Weixian County, Xingtai City, Hebei Province

Copyright © 2022 Hebei Shuangda Rubber Machinery Co., Ltd.